COMPANY

WE COMBINE THE DRIVE OF INNOVATION

WITH THE EXPERTISE OF TRADITION

Main Tech is a dynamic Italian Company offering a new generation of equipment and engineered complete systems for bulk materials in granules or in powder for the plastic, chemical, pharmaceutical and food industry. Launched and led by people with many years of work in the field, Main Tech combines a culture of innovation with the wisdom of experience to develop better and better its products and services.

Located in the North- East of Italy, Main Tech has the advantage of being part of a region influenced by the Petrochemical Industry since the beginning of 50’s leading to radical development and knowledge for those operations related to the conveying and treatment of plastic material first and bulk materials in general.

WE COMBINE THE DRIVE OF INNOVATION

WITH THE EXPERTISE OF TRADITION

Main Tech is a dynamic Italian Company offering a new generation of equipment and engineered complete systems for bulk materials in granules or in powder for the plastic, chemical, pharmaceutical and food industry. Launched and led by people with many years of work in the field, Main Tech combines a culture of innovation with the wisdom of experience to develop better and better its products and services.

Located in the North- East of Italy, Main Tech has the advantage of being part of a region influenced by the Petrochemical Industry since the beginning of 50’s leading to radical development and knowledge for those operations related to the conveying and treatment of plastic material first and bulk materials in general.

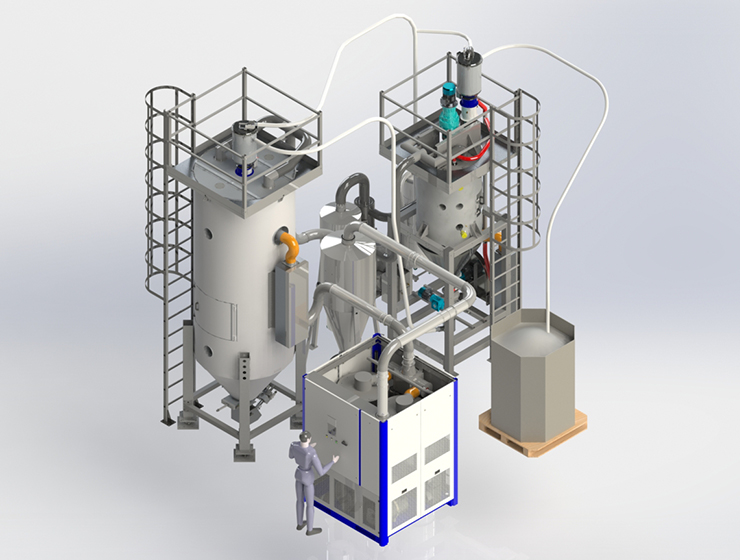

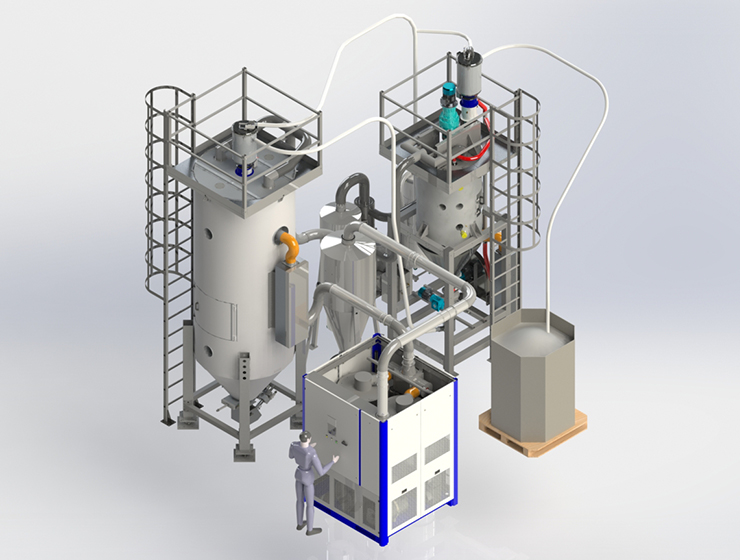

At Main Tech, we design and manufacture complete solutions for the handling, storage, dehumidification, dosing, and recycling of granular and powdered materials. Thanks to a perfect balance between a young, dynamic team and solid technical expertise, we tackle our customers’ challenges by providing innovative, customized, and reliable systems.

We specialize in the plastic processing industry and bulk materials, designing systems that meet the needs of every sector. We offer advanced solutions for applications in various fields, including polymerization, compounding, rubber, PVC extrusion, film, injection, rotational molding, as well as the food and chemical industries.

We provide a full range of equipment for the creation of centralized transport and dehumidification systems, including:

• Vacuum blowers with side channels, claw-type, and Roots lobe-type, available in various power ratings and vacuum levels.

• Filtration devices, custom-designed to meet specific requirements.

• Material receivers for granules, flakes, or powders, with capacities from 2 to 200 liters as standard and up to 2000 liters for special applications, equipped with flap discharge or butterfly valve.

• Automatic material selection units for Industry 4.0 management, integrated with PLC controls and process supervision systems.

Main Tech designs and manufactures machineries dedicated for complete material handling systems as well as storage, material drying, dosing and recycling systems, for both granules and powder materials. The young spirit and firm technical maturity, enable Main Tech company to overcome the challenges of clients by finding special solutions both reliable and cost effective. Main Tech skillful in-house engineering department supports brand new projects and customized turn-key systems, according to the specific and special needs of customers. In the plastic industry, Main Tech provides dedicated solutions for all the applications in extrusion, compunding, rubber production, injection molding, blow molding and roto-molding.

NOT A SUPPLIER BUT A PARTNER

Our philosophy is to approach customers with the mindset of a partner, not just a supplier. The combination of our youthful spirit and solid technical experience enables us to design and create advanced solutions for the handling and transportation of plastics. We focus on high-quality materials and innovative technologies to meet the specific needs of our clients.

Our goal? To optimize your production processes, reduce waste and energy consumption, and improve the quality of final products, always with a focus on continuous improvement and efficiency.